consumers through endless R&D with beliefs in passion, honesty and sincerity.

Food Ingredient

Jung Ang Tafla’s products for processing various food items are made with advanced research facilities, including pilot production facilities and analysis instruments, and accumulated technologies and know-how for independently handling all processes related to products, including extraction, concentration, spray drying, vacuum drying and mixing. The company manufactures powdered, pasted and concentrated products using various materials for agricultural processing, marine processing, livestock processing and dairy processing.

Food Manufacturing and Processing

Food Manufacturing and Processing

Soybean Milk Drinks

Functional Health Food

Facilities for Producing Food Ingredients

Weightless Mixer

Two shafts equipped with paddles in a mixing chamber symmetrically rotate ingredients in the inner upward direction to make them float and form a weightless area (note: mixing area) by inertia, enabling powder with poor fluidity to be effectively, swiftly and safely mixed.

One Spray Drier

Spray drying is about making the original liquid within hot air fine particles using a disk and spraying them in a drying chamber. Particles which are sprayed contact hot air momentarily and are dried and become powder after water evaporates. Products which are sensitive to heat can become powder and manufactured powder which is porous is highly soluble.

Two Three-Roll Mills

A three-roll mill homogeneously disperses and grinds viscous substances with energy produced owing to compression, shearing force and friction which three rolls generate through different directions and rotation speed. Narrow gaps between rolls, rotation of different directions and frictional force by rotation of different speed make products of fine particles.

Two Vacuum Concentrators

When extracts are boiled in the vacuum state, they evaporate at low temperature and it is possible to evaporate much water in a short time. It is possible to reduce deterioration of products as much as possible through attempting vacuum concentration of ingredients which can be deteriorated when they are heated until the boiling point under normal pressure or ingredients which are decomposed because of air or respond to air.

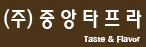

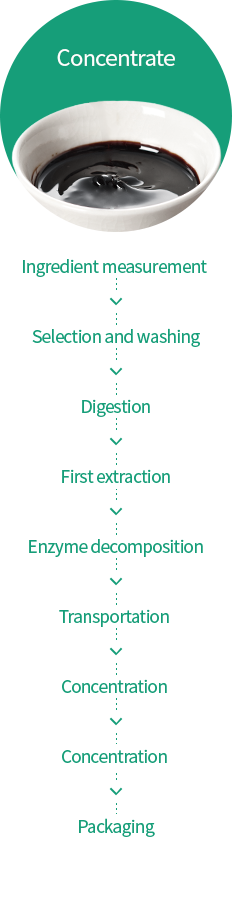

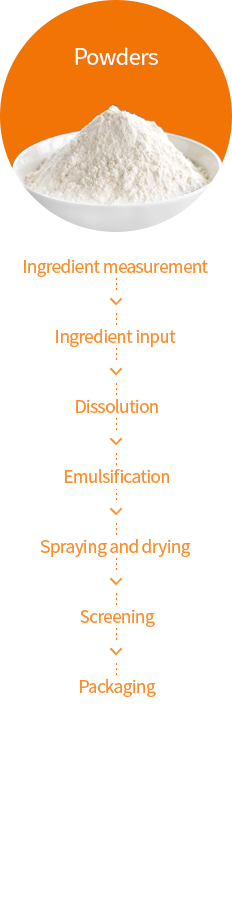

Manufacturing Process Chart

List of Food Ingredients

| Product Groups | Types of Raw Materials | Product Names |

|---|---|---|

| SeasoningsView | Dairy products | Whipping Cream Powder |

| Butter Powder | ||

| Yogurt Powder | ||

| Cream Butter Powder | ||

| Cheddar Cheeses Powder | ||

| Mixed milk products | ||

| Agricultural· marine and livestock products | Beef Base Powder | |

| Shank Bone Concentrate Powder | ||

| Anchovy Extracted Powder | ||

| Cuttlefish Extracted Powder | ||

| Katsuobusi Extracted Powder | ||

| Seasoned Chicken-Tasted Powder | ||

| Chicken Curry-Tasted Seasoning | ||

| Chicken Bouillon Powder | ||

| Sweet potato-tasted seasoning | ||

| Mixed Vegetable Juice Powder | ||

| Sesame Oil Powder | ||

| Coffee Seasoning Powder | ||

| Seasoning Powder | ||

| Vegetable Decomposition Protein | ||

| Lemon Juice Concentrate Powder | ||

| Orange Powder | ||

| Others | Lemon-Flavored Powder말 | |

| Snack Base Powder | ||

| Cracker Seasoning | ||

| ConcentrateView | Agricultural products | Black Bean Concentrate |

| Brown Rice Concentrate | ||

| Wheat Syrup | ||

| Corn Concentrate | ||

| Black Rice Concentrate | ||

| Ginger Extracts | ||

| Beef Concentrate/td> | ||

| Shank Bone Concentrate | ||

| Marine products | Shellfish Concentrate | |

| Cuttlefish Concentrate | ||

| PastesView | Nuts | Almond Paste |

| Pine Nut Paste | ||

| Walnut Paste | ||

| Nuts Mix Paste | ||

| Peanut Paste | ||

| Seeds | Black Sesame Paste | |

| Flaxseed Paste | ||

| Sunflower Seed Paste | ||

| OthersView | Refined Fish Oil (DHA) | |

| Borage Oil | ||

| Red Ginseng Concentrate | ||

| Sweet Pumpkin Powder | ||

| Danggwi Concentrate | ||

| Lactose | ||

| Honeyberry Concentrate | ||

| Black Bean Powder | ||

| Garlic Concentrate | ||

| ‘Seonsik’ Powder | ||

| Lemon Concentrate | ||

| Orange Concentrate | ||